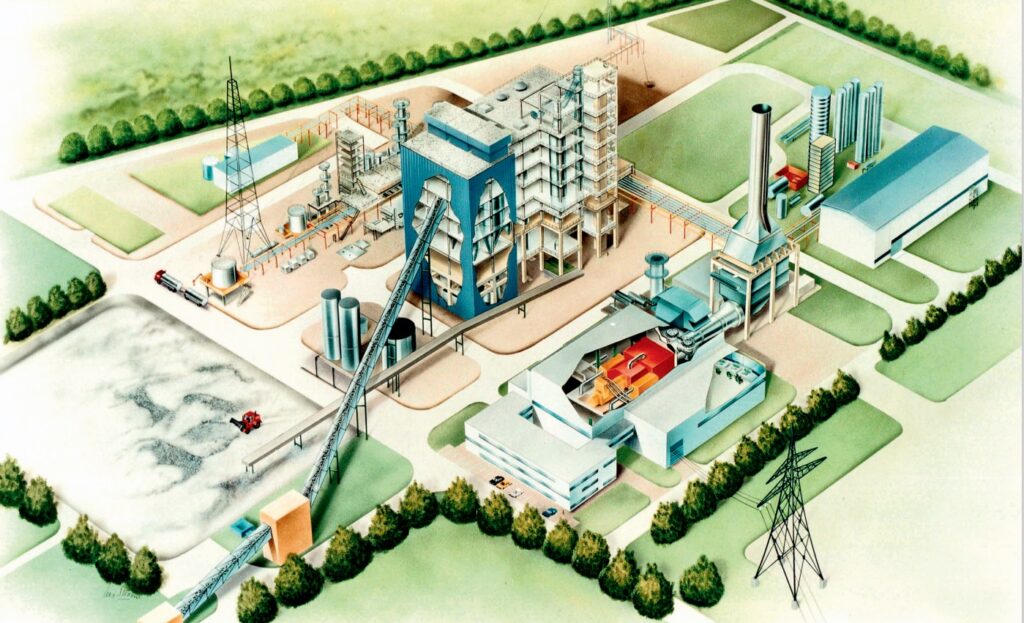

Coal gasification (CG) was developed in The Netherlands from 1993 – 2013. During this period a 250 MW pilot power plant was designed, built and operated by an excellent team of experts at Buggenum, see below and the History of Coal Gasification at Downloads (both in English and Dutch).

Design pilot plant at Buggenum, The Netherlands (250 MW, 1993 – 2013)

Pilot plant at Buggenum, as built

Succesful

The pilot plant in Buggenum was succesful enough to make NUON, its owner, decide to build the first full scale commercial plant in the Eems Harbour in the north of The Netherlands. The permits were promptly granted by the Province of Groningen, so the Magnum Plant could soon be build….

However, after a few months environmentalist groups protested against the construction of the plant, since the emission of mercury was believed to be too high in the vicinity of the Waddenzee, a protected sea-area at the north of The Netherlands.

No decimation of CO2-emissions

Although these emissions of mercury would have partially counterbalanced the emissions of mercury originating from natural gas extractions (that could have been reduced), the sad result was that the permit for the first commercial coal gasification plant in NL was finally withdrawn.

Had this not be the case, there would have been >100 coal gasification plants througout the world already, that would currently have lead to significantly lower global CO2-emissions, so probably less climate change. Especially the dirtiest lignite fired power plants in some countries would already be converted into coal gasification plants, thereby decimating national CO2-emissions.

Too innovative…?

Untill today not a single coal gasification plant is built in The Netherlands yet, which is a shame. Although there was a second opportunity for building 3 ultramodern coal gasifcation plants in 2008 – 2012, it was concluded that coal gasification was “too innovative”….. Therefore, it was decided that 3 traditional coal fired plants should be build in The Netherlands: two at Rotterdam Harbour (the Onyx Plant and the MPP3 Plant) and one at the Eems Harbour (the Eems Plant). Total capacity of these plants currently is 3,360 MW.

Nevertheless, in 2020 the Dutch Government already intended to close these three, almost new coal fired plants again (!), since CO2 emissions of coal fired plants were regarded too high when compared to natural gas fired plants. This was however before the war in Ukrain.

Ukrain war

The war in Ukraine changed everything again. Therefore, all coal fired plants in NL are now still in operation, since there is a European ban on Russian natural gas. Moreover, since the Dutch had also decided to close down all gas extractions at “Groningen” (by far the largest source for natural gas in Europe), there is a big shortage on natural gas in NL now. Therefore, The Netherlands have to import LNG (Liquified Natural Gas) from Qatar and the US, which however is very expensive and not very sustainable either: the LNG from the US even originates from fracking gas.

CO2 capture: CCS

Currently however, there is a new opportunity for CO2 capture at two of the three abovementioned coal fired plants. If executed, the captured CO2 of the Onyx Plant and the MPP3 Plant at Rotterdam Harbour can be stored in empty gas fields at the North Sea: the PORTHOS-project. However, the energy consumption of this technology is huge: > 20% of all generated power must be used to capture the emitted CO2, leading to high operational costs, next to high investment costs. The generated electricity will therefore still be expensive.

Turquoise hydrogen

All three coal fired plants should therefore be transferred into coal gasification plants. CO2 will then be harvested rather easily as a pure by-product, while coal gasification also leads to the production of massive amounts of blue or turquoise hydrogen, especially when the capacity would be doubled. In that case a huge amount of cheap blue/turquoise hydrogen can be generated, leading us smoothly into a durable and sustainable hydrogen based economy.

Fast transformation

Moreover, coal gasification technology is the only CO2-neutral technology that is available on the short term. It has a Technology Readiness Level (TRL) of 9 (= the highest level) and can be integrated by “simply” replacing old coal fired plants by coal gasification plants. This should be rather easy since permits and logistics around coal processing are already there.

No other CO2-neutral technology is available instantly, be it:

- solar or wind: not enough room and not enough capacity on the grid*.

- nuclear with uranium: not ready within 12 – 15 years.

- nuclear with thorium: not ready within 15 – 20 years.

- nuclear by fusion: not ready within 20 – 30 years.

- geothermal: just starting to be developed.

* Untill recently, The Netherlands was nr.1 worldwide in solar power per inhabitant. Due to serious limitations on the grid however, sales have dropped dramatically already (november 2023).

However, if we start today with coal gasification, the first commerical plant could be producing CO2-neutral hydrogen and electricity by 2026 already.